Fast & Accurate ENS GB & EU ICS2 Solutions Built for You.

Simplifying Trade Compliance with Integrated WMS Service

-

Freya Jane

- Director of Customer's Success

Every organisation that manufactures goods worries about maintaining the lifecycle of the goods from raw form to finished product. Poor management has resulted in financial losses despite having warehouses for internal business. Hence, software known as a Warehouse Management System (WMS) is created specifically to handle a warehouse’s operations.

The Warehouse Management System (WMS) has a significant impact on operational efficiency. The research revealed that,

“A remarkable 26% of WMS users have experienced substantial time savings.”

This data underscores the transformative potential of WMS in streamlining warehouse processes and improving overall productivity.

This article describes WMS’s functions, goals, and connections to TMS, ERP, and inventory control. Moreover, it will also explain why WMS is so crucial for customs declaration, the difficulties firms have with WMS management, and the best ways to deal with these issues using iCustoms CDS software.

Understanding WMS (Warehouse Management System)

Warehouse Management System is a specialised software which helps warehouses to operate more efficiently and effectively. It tracks inventory, processes orders, and more. It serves as a warehouse’s primary intelligence, effectively controlling inventory and guaranteeing precise stock information.

The WMS warehouse system aids businesses in overseeing their storage facilities, from receiving raw materials to shipping. It is essential to supply chain management (SCM) because it provides constant access to detailed information about all of a company’s stock, wherever it may be.

Features and modules of WMS

- Inventory Management

- Order Management

- Labor Management

- Financial Management and Reporting

Types of WMS softwares

Various kinds of warehouse management system software are available based on the nature and scale of the enterprise.

Standalone system

Various kinds of warehouse management system software are available based on the nature and scale of the enterprise.

ERP Module

A specialised part called the Enterprise Resource Planning (ERP) module for Warehouse Management System (WMS) is of an ERP software suite which helps to control and improve warehouse operations.

Cloud-based platform

Cloud-based warehouse management systems (WMSs) are hosted and sent out via the cloud computing infrastructure rather than kept on a company’s servers or hardware. Users access applications and data on third-party servers online.

Supply chain module

A supply chain WMS module is a specialised component of an ERP or WMS that optimises and manages warehouse operations within a supply chain.

How is WMS integrated with supply chain modules?

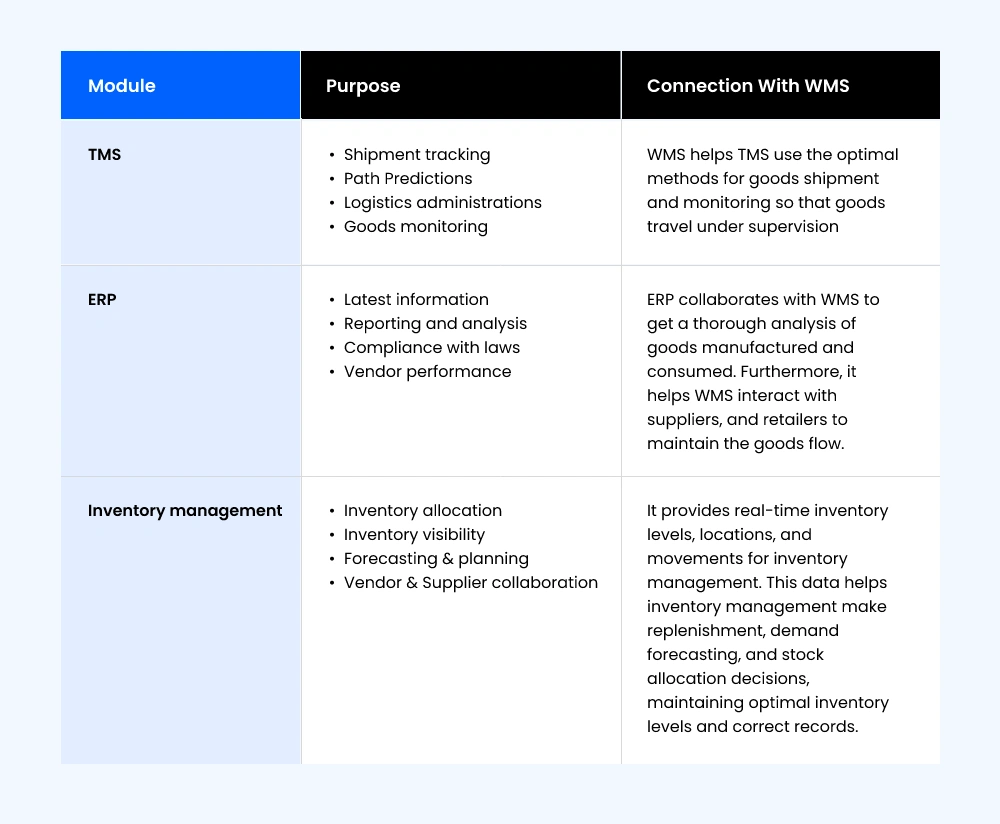

In general, the supply chain has a variety of modules specifically designed for different fields like finance, technical backend working, human resources, etc.

Since we are discussing warehouse systems, the modules of the Transportation management system (TMS), Enterprise Resource Planning (ERP), and inventory management have direct connections.

Let’s dive in and understand at what levels they are inter-correlated with WMS.

Role of WMS in customs trade compliance

In the context of international trade, warehouse systems are crucial in guaranteeing customs trade conformity through increased efficiency and precision in warehouse operations. WMS helps companies comply with customs laws and standards by automating several procedures and providing real-time inventory and shipment data.

1. Boosting inventory management:

For starters, WMS makes it easier to track and account for a company’s inventory. This aids in avoiding discrepancies or mistakes in inventory records that can cause regulatory problems.

2. Customs reporting:

WMS systems permit precise and timely reporting to customs officials. They create shipping manifests and customs declarations according to local regulations. This lessens the possibility of being held up at customs and the possibility of incurring penalties for failing to comply.

3. Enhancing customs safety:

WMS also helps with things like product identification and tracking. It’s useful for keeping tabs on how items are handled in the warehouse and where they go in the supply chain. This tracking system makes storing and transporting hazardous or prohibited goods safer.

4. Boosting productivity:

WMS also helps businesses streamline their operations, decrease the number of mistakes made, and boost their productivity. Reduced customs delays and a more continuous flow of goods across international borders help ship and deliver goods faster.

As a whole, WMS is an important part of customs trade compliance since it aids businesses in fulfilling their legal obligations, reducing their exposure to risk, and keeping their advantage in the global market.

Integrating iCustoms and WMS: The Role of iHub in Streamlining Supply Chain

iCustoms is an AI-based CDS software that helps businesses with customs trading. It has several services that provide different helping tools in order to get efficient customs clearance. iCustoms software is user-friendly, provides reliability, and is an optimal intelligent solution for managing customs compliance.

When evaluating iCustoms services, many companies share a common concern: whether or not iCustoms can be seamlessly integrated with other components of the supply chain, most notably WMS. To solve this problem, iCustoms has developed a dedicated feature called iHub, which is meant to link the supply chain modules with the iCustoms services.

IHub functions as a connector, facilitating seamless integration between modules such as Supply Chain Management (SCM), Enterprise Resource Planning (ERP), Transportation Management System (TMS), and Warehouse Management System (WMS) via their respective APIs.

Example:

Consider a manufacturer that wants to export goods but struggles to manage WMS and find CDS software that can handle declarations and inventory. In such a situation, iCustoms emerges as the ideal solution. iCustoms offers a streamlined approach, allowing simultaneous processing of WMS and customs clearance, eliminating complications.

iCustoms takes charge of shipment and monitoring responsibilities, while internal warehouse operations can be efficiently managed through WMS.

Furthermore, iCustoms collaborates seamlessly with other supply chain components to create a comprehensive hub, effectively managing both customs and supply chain activities.

Benefits of using integrated WMS system UK

Conformity with regulations:

Using iCustoms’ intelligent automation system helps organisations manage warehouse stocks while complying with new laws.

Save money:

Using iCustoms integrated software can cut labour costs dramatically. Businesses that embrace iCustoms can cut expenses and increase profits.

Improved efficiency:

The most significant benefit of combining WMS and iCustoms is the enhancement of efficiency and accuracy in process management.

Increased precision:

Businesses need intelligent documentation processes that reduce work, errors, and online monitoring without adding dangers in today’s technology-driven world.

Effective record-keeping:

WMS software can automatically generate shipping manifests and declarations, two types of customs paperwork. Automation of this sort speeds up the paperwork and shortens the time needed for customs clearance.

Conclusion

Businesses are able to traverse the complicated world of customs rules with ease thanks to the seamless integration that iCustoms provides with WMS and other components of the supply chain.

This integration not only ensures adherence to rules but also translates into cost savings, better efficiency, and enhanced precision in the administration of processes.

By going with iCustoms, companies can improve the efficiency of their operations, cut down on potential risks, and keep a competitive edge in the global market.

FAQ's

How does a warehouse management system work?

Warehouse Management Systems (WMS) utilise software and technological infrastructure; its core functionalities include:

- Inventory Management

- Order Fulfilment

- Warehouse Layout and Storage Optimisation

- Labour Management

- Shipping and Receiving

- Data Integration

What are the four types of warehouse management systems?

Following are the four types of warehouse management systems:

- Standalone WMS

- Supply Chain Module WMS

- ERP-integrated WMS

- Cloud-based WMS

Is WMS a type of ERP?

No, WMS (Warehouse Management System) and ERP (Enterprise Resource Planning) are different systems:

- WMS focuses specifically on warehouse operations and inventory management, like tracking goods, picking orders, and optimising storage space.

- ERP is a broader system that manages all aspects of a business, including financials, customer relations, manufacturing, and even HR. While some ERPs might have built-in WMS functionality, they're not the same, and WMS often integrates with larger ERP systems.

You may also like:

Automate Your

Customs Process

Reduce Paperwork, Improve Accuracy & Enhance Customs Compliance

Subscribe to our Newsletter

About iCustoms

Automate Your

Customs Process

Reduce Paperwork, Improve Accuracy & Enhance Customs Compliance